Magnetic Particle Inspection

MT Advantages

- Sensitivity to Surface Defects

- Rapid Inspection

- Real-time Results

Optical Emission Spectroscopy, or OES analysis, is a rapid method for determining the elemental composition of a variety of metals and alloys. The newest handheld models have made CE testing more compact and affordable.

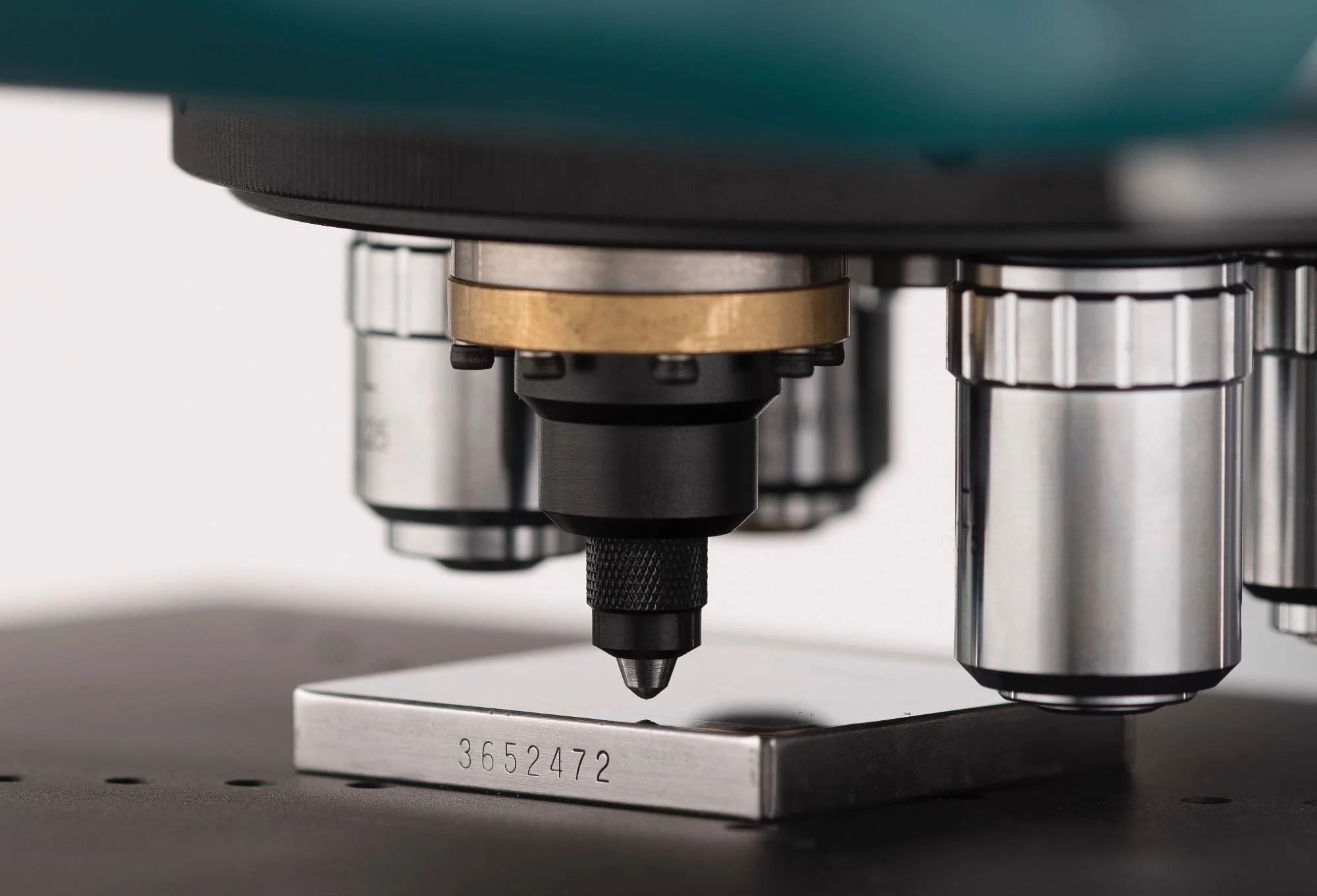

Hardness testing is a non-destructive test method that involves applying a constant load via a rounded or pointed object, under controlled conditions, to create an indentation in a metal surface. This is then measured to determine the hardness of the material.

Ferrite testing, also referred to as a ferrite scope test, is a rapid non-destructive inspection method used to measure the amount of delta ferrite in austenitic stainless steel and duplex stainless-steel materials. Ensuring proper ferrite content ensures corrosion resistance, durability, and crack prevention.

Advantage Quality Services is a distinguished company, wholly owned and operated by proud members of the Metis Nation of Alberta. We maintain a robust standing with organizations like the Workers' Compensation Board (WCB), and our dedicated employees hold certifications in accordance with national standards, including CSA and Can/CGSB 48.9712.